Fixing a Flooding Carburetor

This bulletin covers the following Champion Power Equipment models: All Champion Power Equipment Engines that run on gasoline.

- To reduce the risk of injury, user must read and understand the operator’s manual before using this product.

- DO NOT make any adjustments to the generator without first stopping the engine and disconnecting the spark plug wire.

- Burns from hot parts — let the engine cool completely before touching hot parts.

- Injury from moving parts

- To reduce the possibility of fire or explosion, be careful when working around gasoline. Keep cigarettes, sparks and flames away from all fuel‐related parts.

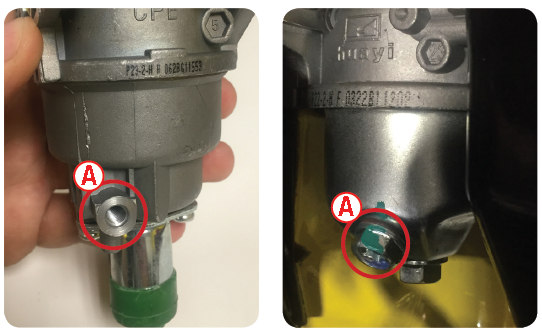

When the carburetor is leaking fuel, it probably has debris caught in the float needle valve area. This valve is located at the point inside the carburetor where the fuel line attaches to the carburetor itself. By removing the fuel from the carburetor, at the drain bolt at the bottom of the float bowl (A), you will be able to lower the float valve for cleaning the debris off of it.

Visual

Now remove the fuel line at the petcock and using a light blow of compressed air of a petrochemical aerosol spray (WD-40, starting fluid, carb. spray, choke cleaner) and give a couple of bursts of this air or fluid down the fuel line. This will wash away the debris and allow the float valve to seal again, preventing unchecked fuel into the carburetor. If it possible you need to perform this repair more than once, in case the first try fails to correct it. If it fails to solve the fuel flooding issue, then remove of the float bowl will be necessary to inspect the float for any fuel entry inside the float itself. The weight of the fuel can prevent the float from raising the float valve and sealing fueling entry into the carburetor.

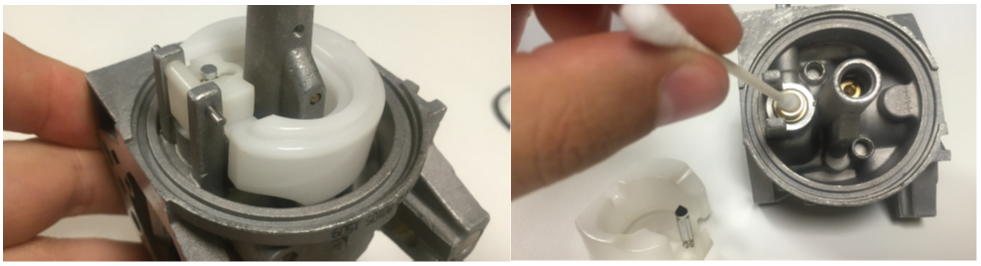

The float can be removed by taking away the pivot pin that the float hinges on (B). Most float removals will bring the attach-float needle valve with it. Take a Q-tip cotton swab with some WD-40 on it and cleaning the needle seat, will remove any debris or varnish buildup inside the valve body area.

Visual

A cloth with some WD-40 can be used to clean the rubber tip of the float needle also. Be sure to wash both the needle and needle seat areas with aerosol spray cleaner to eliminate any remaining debris after cleaning. Reassembly should solve your flooding problem.

View and download the PDF version here.